News

Aluminum extrusion flat belt lifting conveyor - APL CONVEYOR Automatic ENTERPRISE CO.,LTD |

In the past assignment style, the packaging and weighing of screw parts used a lot of manual labor. With the progress of industrial automation, this operation process can also be replaced by conveyors.

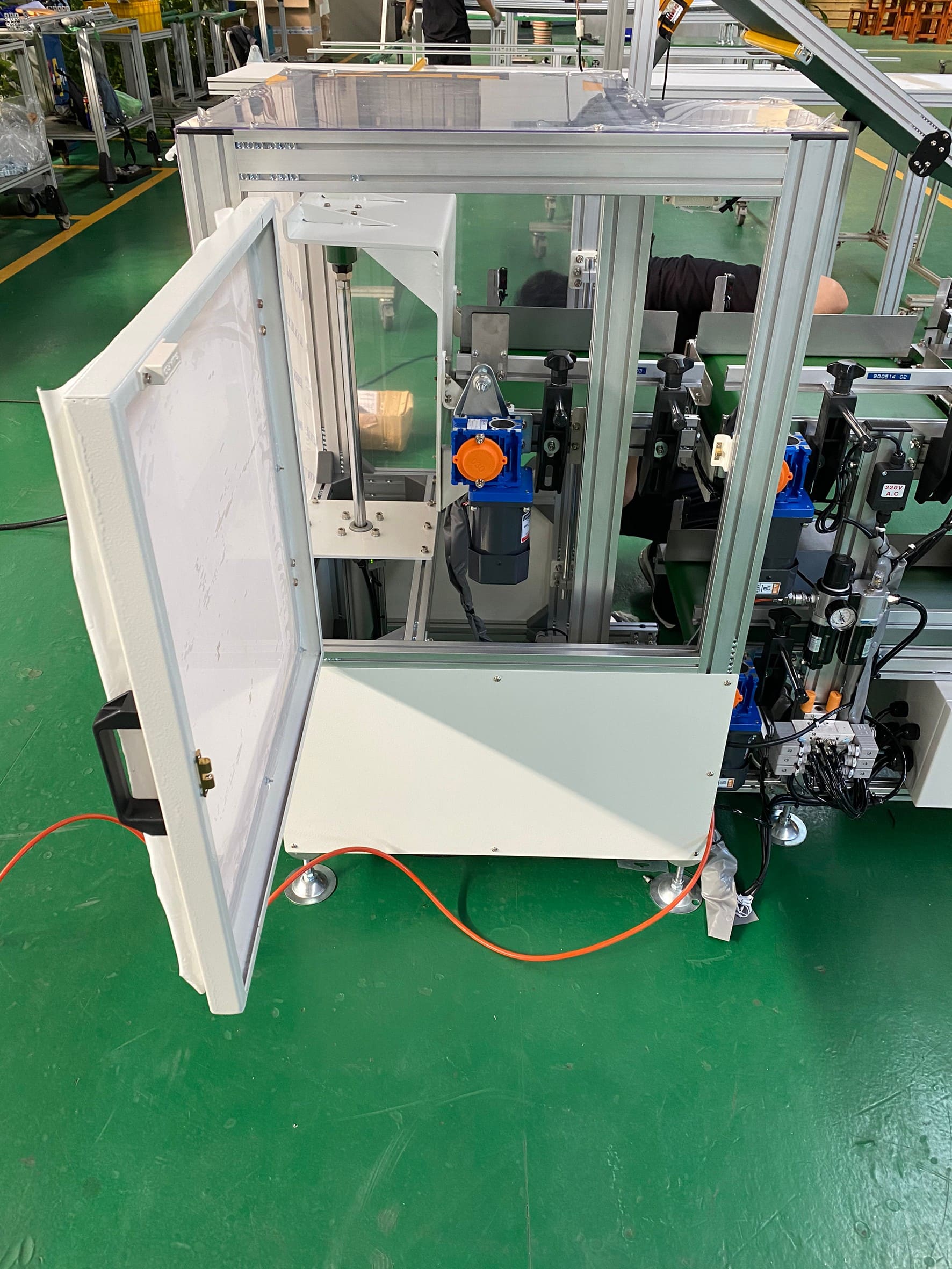

This time, I helped the guests plan a set of aluminum extrusion belt conveyors with the upper and lower floors. The operators on site only need to put the cartons into the entrance of the upper conveyor belt, and the cartons are transported forward through the conveyor. When they reach the fixed point, the screws are sent through the feeding to the carton, with a vibration motor to shake and flat the screws in the carton. Then the cylinder is positioned, and the cartons are sent down through the lifting conveyor, returned to the original feeding end, and take away by the on-site personnel.The use of the production line with conveyors not only improves efficiency, but also reduces a lot of labor waste.

Yuan Yu’s automatic conveyor machine systems have been using in wide ranges of different industrials and conditions. From traditional industry to electronic industry all need to use it and also plastic injection-molding, metal detector conveyors, restaurant process conveyors, aluminum extrusion conveyors, inkjet coding and marking conveyors, wood processing conveyors, labeling conveyors, food processing conveyors, conveyors for punching, iron turning conveyors, automatic packing machine, bar storage racks, blow molding machines, clothes washing conveyors, racks with hoist systems, safety fence, agricultural conveyors, aluminum extrusion wood workbench. Let the products of Yuan Yu become a critical element on your production line! |

| Back |